If you have ever seen the small ammeter with a pointer moving over a calibrated board , one thing that can captivate you is how on earth does the pointer move and how accurate does it measure? Could it be that a genius calibrated the board using super powers or super human strength .You might even think that those that can thoroughly explain them are simply genius with dual core processor brains . Well this post attempts to demystify that for you. Join me as we take a tour through indicating instruments and by the time we are done , you would be like those genius you envy.

Every day we are faced with the job of determining what amount of one thing or the other is required to do certain task . Measurement is a core part of not just engineering but our daily lives. Watch this, how do I get to know the exact amount of water to make a nice pot of soup or the exact quantity of eggs to make a sumptuous pancake? But more importantly, measurement is important in engineering because in several engineering process,precision and accuracy is a highly sought after quality hence errors are are prevented as much as possible . Accuracy in ascertaining the right values of quantites being measured is very crucial to engineers and scientist hence to an engineer, measurement is not about having a nice meal, rather,it is about getting the job done.

MEASUREMENT

Adapted from pixabay under CCO licence

In our daily lives, we measure with several things ranging from crude methods like using the hand to determine the right quantity of salt to using teaspoons to measure sugar for a cup of coffee. But remember that in engineering, errors are greatly frowned at hence the need for more complex but accurate systems that can almost perfectly measure various engineering quantities with minimal error that might be involved in the measurement process.The systems used for measuring in engineering are called instruments.Now their exist a wide range of measurement today that the first task an engineer faces is even decicding on which instrument but just before any kind of instrument is selected , there are some salient questions to be asked

BEFORE YOU START MEASURING

Before proceeding to any form of measurement, certain key questions needs to be asked in other to properly help maximize the whole process. First is what quantity is actually being measured? An engineer needs to ascertain the quantity he wants to measure before he can decide on the best method to employ.Quite simple right? Now that leads to the next question which is what instrument is the best for the measurement. Several instruments exist to measure a single quantity hence he needs to ascertain the actual instrument that is best for the job.Another important question is how would the result obtained be affected by the environment, the quantity being measured and how would the instrument itself affect the quantity being measured. These are part of the headaches an engineer has to go through before beginning any design or even carry out any form of measurement.

INDICATING INSTRUMENTS

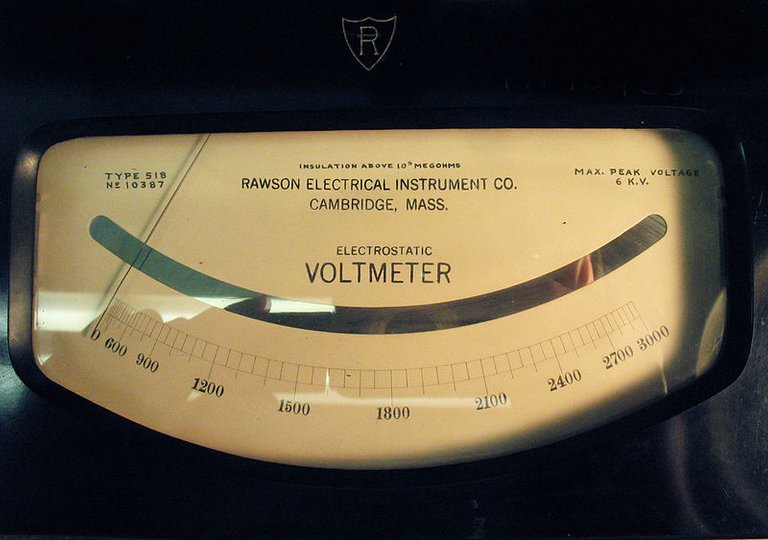

Most instruments with pointers fall under the category of instruments called indicating instruments.They generally consists of a pointer which moves over a calibrated board to indicate the values of the quantity being measured.

A practical indicating instrument

Image from wikipedia under the Creative Commons CCO 1.0

SO HOW DOES THE POINTER GETS TO MOVE

the pointer moves right ? then if you take a quick glance at your college physics, you would remember Newtons third law of motion. Now it is not all that complex.Permit me to paraphrase it this way : all things would remain in their state of rest or if moving move with a uniform motion except they are acted upon by an external force. Hence if the pointer is moving , then it has to be responding to the influence of a force acting on it. Let me push this further, what we need really is not just a force acting on the pointer, what we need is a force that can cause the pointer to move or better still to rotate so what we really need is a torque. Torque is the rotational effect of a force or in a layman language a force that produces a rotational effect.

WHERE DOES THE TORQUE COMES FROM?

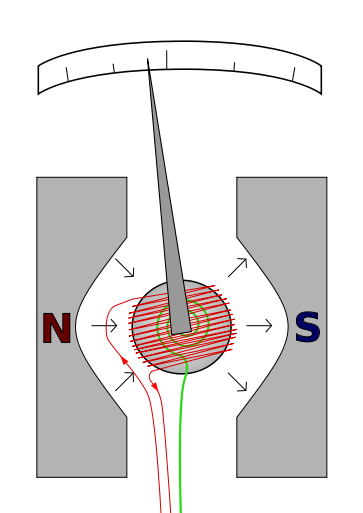

Now to generate this torque , The different instruments employ different means which still aligns with the laws of physics. The common one is that when current flows through a conductor placed in a magnetic field, a force acts on it . So a conductor is placed in the middle of a strong magnetic field and wires are connected to it which woiuld be connected to where the measurement is to be taken hence as the current passes through it, a force acts on the pointer causing it to move.We call instrument like this Permanent Magnet Moving Coil Instruments (PMMC).

Another method is to use a principle in physics which states that a mechanical force exists between two current carrying conductors hence the pointer can be placed between two conductors carrying current thus the mechanical force acts on it.Instruments like this are called Dynamometers.

THE THREE IMPORTANT TORQUE

Now for the instruments to work properly, it takes more than just making the pointer to move. There are also other things to take care of. We need three types of torque.The one I explained earlier on how to get the pointer to move is called the deflection torque but it cant do the job alone. There are three important torque that must relate well with themselves like the amazing avengers superheroes in other to get a wonderful instrument.The better they relate , the better the instrument.

DEFLECTION TORQUE

This is the torque I have been explaining in earlier sections. This is the torque responsible for the actual movement of the pointer. The instrument must be properly arranged so that a deflection torque is produced.This is achieved via the various means discussed above of obtaining the force responsible for the pointers movement. The deflection torque causes the movement of the pointer hence it must be such that the torque is directly propotional to the value of the quantity being measured.

Obtaining the deflection torque

image from wikipedia under GNU free Documentation Licence

CONTROL TORQUE

If all we had was just the deflection torque, then the pointer would just continue to move indefinitely untilit hits the maximum it can irrespective of the value of the quantity being measured hence we need another kind of torque called the control torque. What it does is quite simple, it is a torque that acts opposite to the deflection torque such that it also increases with an increase in the deflection torque. The goal is that once the deflection torque attains the calculated value for a given current or voltage, then the control torque would also be in place to prevent the pointer from any further movement hence the pointer just stays at the right position where it ought to be.Remember that the control torque increases with increase in the deflection torque hence the pointer would obtain balance when the deflection torque equals the control torque.

SO HOW DO WE GET THE CONTROL TORQUE

Earlier we talked about how to get the deflection torque so how do we get the control torque? There are two primary ways to obtain a control torque although the complexity might differ for different instrument but the principle is the same. The first method is the spring method. Here, we make use of springs to bring about the control torque. The idea is quite simple. The pointer is connected to a spring such that as the pointer moves, the spring twist in the opposite direction. This would make the spring provide an opposite torque which is what we need . More importamntly is that the torque increases with the deflection of the pointer so it gets the job done perfectly.

Another means of obtaining the control torque is using the gravity method. Here, a small weight Is attached to the moving system to obtain the torque. The weight is attached to the pointer such that while it is at zero point, the weight is vertically downward and as it moves, the weight moves in the opposite direction hence exerting a force on the pointer due to gravity as the weight would attempt to retain it original position.

SO WHAT THEN IS THE THIRD TORQUE

Well it seems as though the deflection and the control torque should be sufficient for the instrument to work perfectly well but then one more thing needs to be put into consideration and that is inertia. Due to inertis, the pointer would not rest at a specific point rather , it would be oscillating about a set of value This would sure give lot of headaches as we desire a quick and accurate instrument hence in other to prevent this, we introduce a third kind of torque called the damping torque

DAMPING TORQUE

This type of torque only acts when the pointer is moving and it attempts to oppose the slight change in position of the pointer. The question now would be how do we obtain the damping torque ? There are several ways but I would mention three. They include :

- Air friction damping

- Fluid friction damping

- Eddy current damping

THE INSTRUMENT IS READY

The interaction between these three forces is responsible for the movement of the pointer and how well the system put in place to obtain them determines the accuracy of the instrument. This applies for both domestic and industrial instruments that employs the use of pointers to indicate values on a calibrated board. With basic calculations based on the systems employed to obatinthe deflection, control and damping torque, the scale can be properly calibrated and the instrument is ready for use.CONCLUSION

Engineering instruments are built based on the principles of physics and experiments. Instruments are not products of magic or special brains like I was taught when growing. Rather they are built with basic knowledge of how nature works and how energy relates with themselves.REFERENCES

For further reading, you can check any of the following :

Permanents moving coil instrument

Damping devices for electrical instruments

The three types of torque in instruments

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Dear friend, you do not appear to be following @wafrica. Follow @wafrica to get a valuable upvote on your quality post!

Noted sir. I have done that now.

Great post there, Most dont know the technique through which Electrical instrument works.

Nice exposure

Thanks

Great post. Nice to see the connection between physics and engineering in your post.

Thanks

Nice update between those great course is a joy. Thanks for enlighten me also

This has brought back the memory of the lecture I had back in school on electrical measurements and instrumentation in which the basic operation are mostly based on the concept of electromagnetism in achieving deflections for electrical measurements .

You've done a good job. Kudos!

True. I love that field of engineering . Expect more soonest.

This is great.. I had no idea how these things worked till now.. Great job