Like anything else, googling "How to ____" will overwhelm you with information. When it comes to learning how to build surfboards, here are some of our favorite resources to start:

BoardCAD

Free software that lets you design a board virtually, without having to get your hands dirty, or buy any physical material $$. They have several templates and a feature where you can model a board from an uploaded picture. Highly recommend folks give this a go, as it helped us tremendously.https://boardcad.com/

Greenlight Surf Supply

A kickass guide to refer to anytime you get stuck. They go through the ins and outs of the process, and most importantly they identify which tools are needed.https://greenlightsurfsupply.com/pages/greenlight-surfboard-building-guide-a-z

How to Build a Surfboard

For the more visually inclined (aka everyone) this is a cool video series to visualize exactly what needs to be done at each step of the process. Keep in mind this video series deals with creating an EPS/Epoxy board, which is different than PU/Polyester, but the general process is the exact same.

OK, information overload already? Well here is the process at its bare minimum:

1 - Generate a board design on BoardCAD and then print out the full-size PDF

2 - Get a foam blank (ask a local surf shop for more info, if needed) and trace your design outline with pencil

3 - Cut the outline of the board in the foam blank with a handsaw slightly outside of your pencil marking

4 - Adjust the thickness of the blank by sanding, accordingly

5 - Round off the edges (rails) and try to blend them into the rest of the board

6 - Route out your fin boxes

7 - Lay fiberglass mesh over the board (one layer for bottom, two layers for top deck)

8 - Pour resin over the fiberglass and squeegee it around evenly, removing air bubbles

9 - After resin dries, pour more resin on and use a brush to spread it around

10 - Sand the board down (100 grit first, 320 grit second)

11 - Check that you haven't sanded down too much in any spots (if so, just pour resin over it and sand down cleanly)

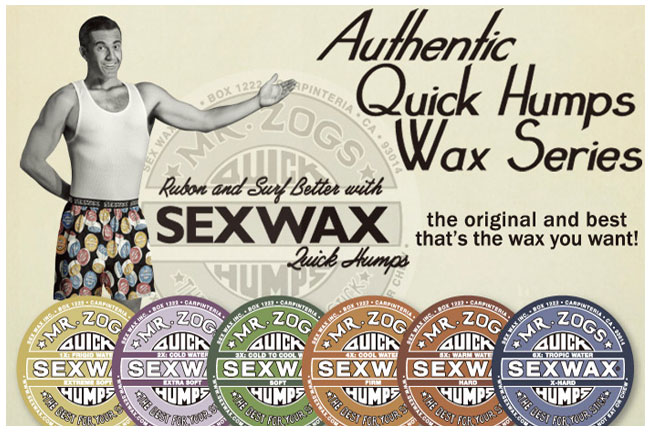

Voila! You have yourself a self-built board. All you need now is some wax!

Sure, your first board (like ours) may not come out as beautiful as you'd hoped. But guess what? It is fun as hell to ride, and if you make a bunch of mistakes throughout the process (like we did), then your second board will be much better because you can avoid these mistakes.

Your third board will be completely dialed and you will be more focused on what color to make it, what pattern to inlay, etc. After that, it's off to the races with creative shapes, lengths, fin setups, etc.

Have a nice weekend. Stay steemy!

I'm collecting the cardboard...

hell yeah Joe! Keep me in the loop, I am curious to see how it works out.

Congratulations @maven360! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP