Scientists are developing new technology 4D printer which produces models that can change its shape when it is exposed to high temperatures. It will be a game changer in many industries as it will cut down the manufacturing cost. Yes, it is true, as per presentations of H. Jerry Qi in 255th National Meeting for American Chemical Society which held in New Orleans, LA last week.

As per Jerry Qi, they are creating a fascinating technology which can change the shape of many industries such as telecommunications, aerospace, medicine, and others. They have prepared a prototype which is quick and agile and can be used for both hard and soft material and also has all the qualities of a traditional printer. He also demonstrated that by connecting wiring directly to the moving structures we can produce more reusable structures which can be helpful in many areas.

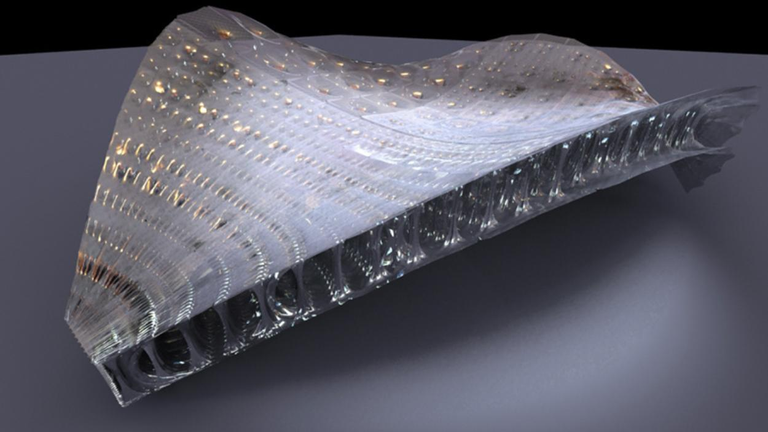

The 4D printer has made by combining four technologies like fused deposition, inkjet, aerosol, direct ink write models. The printer can produce structures with a variety of materials like hydrogels, silver nanoparticle-based, liquid crystals and shape memory polymers. The key element is that the printer is designed in such a way to remember it present state and it will rearrange to its previous state after exposing to high temperatures.

From moon landings to mobile phones, many of the farfetched visions of science fiction have transformed into reality. In the latest example of this trend, scientists report that they have developed a powerful printer that could streamline the creation of self-assembling structures that can change shape after being exposed to heat and other stimuli. They say this unique technology could accelerate the use of 4-D printing in aerospace, medicine and other industries. Source – Science Daily and main Source is American Chemical Society

As per researchers, the major problem in existing 4D printers is that they can produce structures from a single material. In practical cases, it is tough as some structures are made up of different elements. Apart from this the time to assemble and the post-printing task is complex and can be challenging to the industry. The new design of the printer has demonstrated designs ninety percent faster than existing ones.

It can be a revolutionary change in many fields, and there are many practical use cases as per the developers of 4D Printer. Few to mention are Jerry Qi is working with some hospitals in Atlanta to produce prosthetic hands for children. Apart from this, it has many advantages in Manufacturing and aerospace industry. We hope the final product is coming soon to serve the common man.

wow interesting, nice post

This gonna be big and the real game changer. Guess it will be produce for private firm first before getting to the general market.

Super excited to see these become common. I would imagine there will be a lot of shops that set up where you can just send them files and commission their printer to make models for you.

And at that point

Humanity is getting too advanced

Congratulations @brightideas! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPI walked past a Bathroom this morning where the light fitting had fallen on the floor by having the shape changed , because of the heat from the light being left on , so this feature of changing shape already in use!