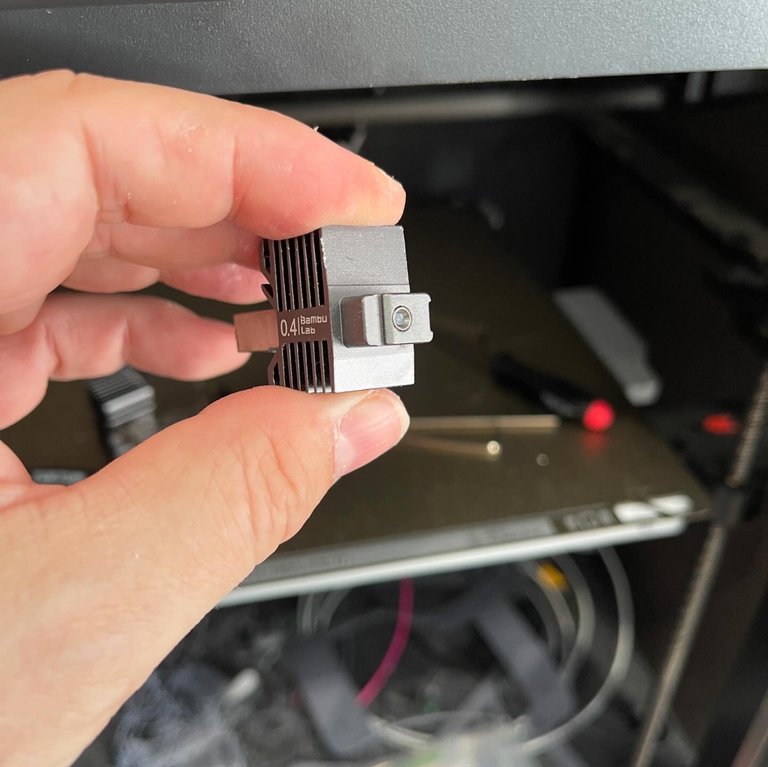

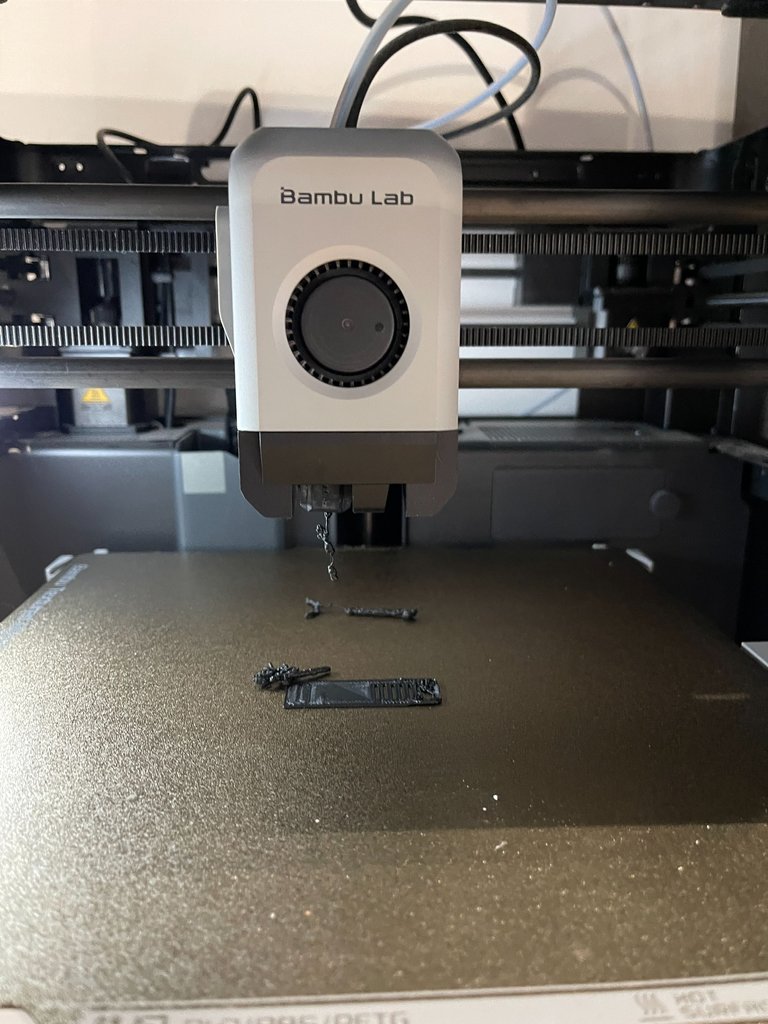

My Bambu Labs P1P finally got a clog that no amount of cold pulls or pushing and praying would fix, so I had to break down and swap the nozzle and heatbreak assembly.

Let me tell you, coming from being able to unscrew the old nozzle and screw in a fresh one on my preious printers, this is a pain and it is messy.

For some weird reason, you can't just change the nozzle.

You have to

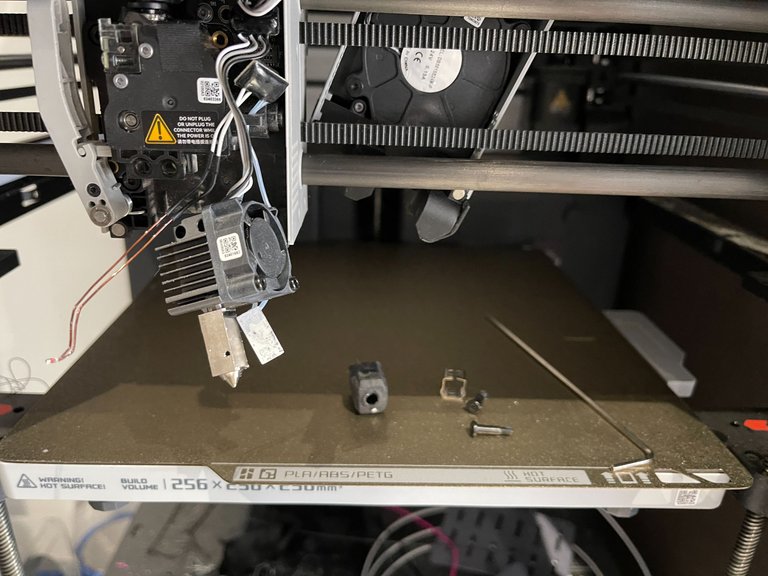

- Remove the magnetic cover and put it to one side (I tuck it behind the x gantry)

- Unscrew the two screws holding the entire hotend assembly in place.

- Remove the small fan by unscrewing the two screws at the bottom.

- Remove the sock.

- Pull off the metal clip securing the thermistor and ceramic heater.

- Peel away the thermistor and heater from the thermal paste.

Then you have to do everything again in reverse with your fresh hotend.

- Splurge thermal paste then squidge the thermistor into the tiny hole and afix heater into the thermal paste.

- Add the metal clip around the heater and thermister.

- Put on the sock.

- Re-attach the fan using the two little screws.

- Screw in the holding screws.

- Replace the front panel.

I don't know about you, but this hardly incentivises me to experiment with different nozzle sizes.

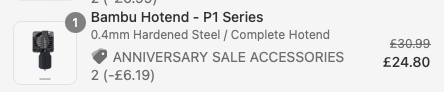

But wait! What is this?

Bambu Labs are having a sale right now, and one of the things in that sale?

Complete hot ends!

Obviously they are still expensive versus just getting the metal piece, but so, so much more convenient.

Unfortunately the 0.2mm hotends were sold out so I can't experiment with printing details.

and swapping the hotend didn't cure my printing woes.

But I am looking forward to not having to do that again, and for the finer nozzle to get back in stock!

Is it worth buying the 0.6mm? I seem to recall it prints slower rather than faster on the Bambu because of flow rates?

Looks like a similar amount of work to changing the hot end assembly on a Dremel. I didn't need to dabble with thermal paste, but there were a lot of screws and a lot of components to unplug.

I have always seen these machines working at 100% of their capacity so it makes me strange to see it still and unassembled hahaha hey but I find it super interesting to finally know its components and how is your hotend, for me the 0.6 is the perfect balance between nozzles spend a little more material but you can get to save a considerable time in work plus you still have the possibility of achieving great results in detail, I have 4 machines and the largest use 0.6 nozzle.

I’ve got a prusa mini with a 0.6mm and it has been great but I hear the Bambu is already at the limit of what it can push through on the 0.4mm?

Might be worth me getting one and seeing for myself I guess!