This post is going to look at 5 different metal 3D metal printing processes that are changing the industry. Each of these printers is trying to improve on the process or develop their own novel process.

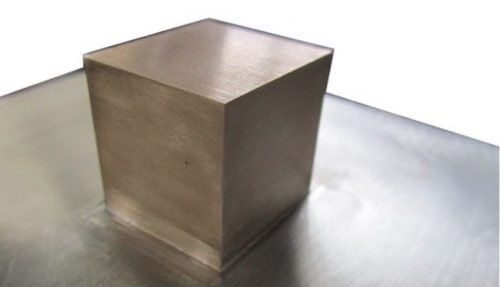

The first company is Aurora Labs. They are developing a large format metal printer that focuses on increasing the printing speed by 100x. Currently their average printing speed is just 3 kg/hr but their goal is 1 ton/24 hrs. They have quite a long way to go but if they are successful they will make metal printing much more competitive and perhaps even favorable to traditional manufacturing. Currently they've shown a 20x20 mm cube as a sample print. This is a long way from large scale but it appears they are focusing on speed and quality at this stage. There is still a lot of work to be done but if they are successful it will be a huge leap in metal printing.

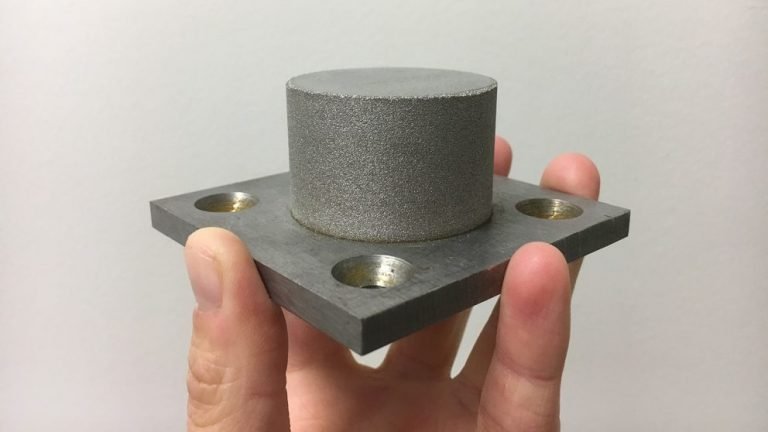

Iro3D is a Seattle based company that is making metal printing affordable. For about $5000 you can be the owner of your own printer. Most printers on the market cost tens to hundreds of thousands of dollars so this marks a significant price drop. Their process is two step and requires a kiln however. The part is printed inside a crucible as a powder. Sand is used as a filler inside the crucible. Once the materials are filled into the crucible it is baked in a kiln. This process is relatively fast (about 24 hrs) and a decent quality for the low cost. Once baked in the kiln and cooled down you simply dump the part and all of the sand out of the crucible. They recommend using a wire brush to finish it up. This is significant because it is a step in making metal printing more accessible to people and will help more industries start to adopt additive additive manufacturing.

Meld Manufacturing is doing things a little different. Instead of melting the metal with a laser they use friction and pressure to produce their parts. This approach lowers the porosity of the printed metal and makes it possible to have more consistent prints. Since it doesn't use a laser there isn't the issue of "spatter." Spatter is when some of the molten powder is ejected off of the printing surface and leaves voids in the print. It is caused by recoil from the laser as well as an ambient gas flow causing inward "entrainment." Another advantage of the Meld process is that it doesn't require lasers or vacuum chambers. Both of these are expensive and drive up prices.

North Carolina State University has done research on printing metallic glass or amorphous metals. These are metals which have a non crystalline structure. Often these are formed by rapid cooling so that the crystal structure does not have time to form. This has meant that in the past they were limited by a critical casting thickness. The researchers have side stepped this problem with how they use their lasers. Their process could mean that amorphous metals can be created in bulk. Amorphous metals have better electrical conductivity which makes the technology appealing. As researchers continue to be able to control material properties in metal printing it will continue to become more and more advantageous to print parts.

Finally, the most exciting and ambitious 3D metal printing project is from the company Relativity Space. Their goal is to be able to 3D print entire rockets on Mars. They use the Stargate printer which has a robotic arm that feeds aluminum wire under a laser. So far they have created a fuel tank that is 7 feet wide and 14 feet tall. They are looking to be able to use their process to go from raw materials to launch in just 60 days. Their Sheppard spacecraft consists of 400 parts, all 3D printed.

For more information check out 3dprinting.com which was the source of the images and much of the information in this post. Thanks for reading!