Whats up fellow Steemians!

Kevin here, bringing you an inside look into my day to day business. Glass Only Repair is a LCD Refurbishment facility located in Northern California. We have clients using our refurbishment services in USA, Canada, UK, and even Australia. Majority of the shops using our service are located in the US but its still cool to deal with people around the world!

When a cell phone repair shop fixes your phone more often than not they will replace a full assembly even when the LED and the LCD is good. This is not an attempt to deceive you. Replacing only the glass on the display can be a very tedious task and requires special equipment to do the process properly. This leaves the shop with one of two options after repair. They can sell the display to a buyback company or they can send it off for refurbishment. This is where we come into play! The following process has been done in China for a long time. There are many new methods coming to the states and if people enjoy this I'll happily continue to update you guys. We are currently working on a new method that involves freezing the displays to -170 and then chipping the glass and glue off the display. As of now the following content is our current day to day.

Below is a sample of inbound orders of iPhone displays. Once we sort them out by the model we test the displays on cell phones for touch as well as test boxes we have that let us check the pixels on all ranges of color.

The next step in the process is removing the frame from the assembly. The frame is a plastic and metal piece that is glued to the glass of your display with either a hot glue or a glue known as cold press glue. This frame holds the LCD and glass in place and holds this front display assembly into the outer metal frame of your phone. We use dikes to cut around the edges of the display and use a food dehydrator to warm them up and peel the frame off.

We have hotplates that are attached to vacuum pumps. These hotplates hold the LCD in place so we can run Molybdenum wire through the glue that holds the glass to the LCD. The glue is called OCA ( Optically Clear Adhesive). We removed the frame in the previous step to give us cleaner access to run the wire without damaging the display.

Here is gif time-lapse video of glass being removed on a samsung display. On this video, you will see me rub the OCA off the displays polarizer. This is common for samsungs but on iPhones we replace every polarizer and the mess of OCA with it.

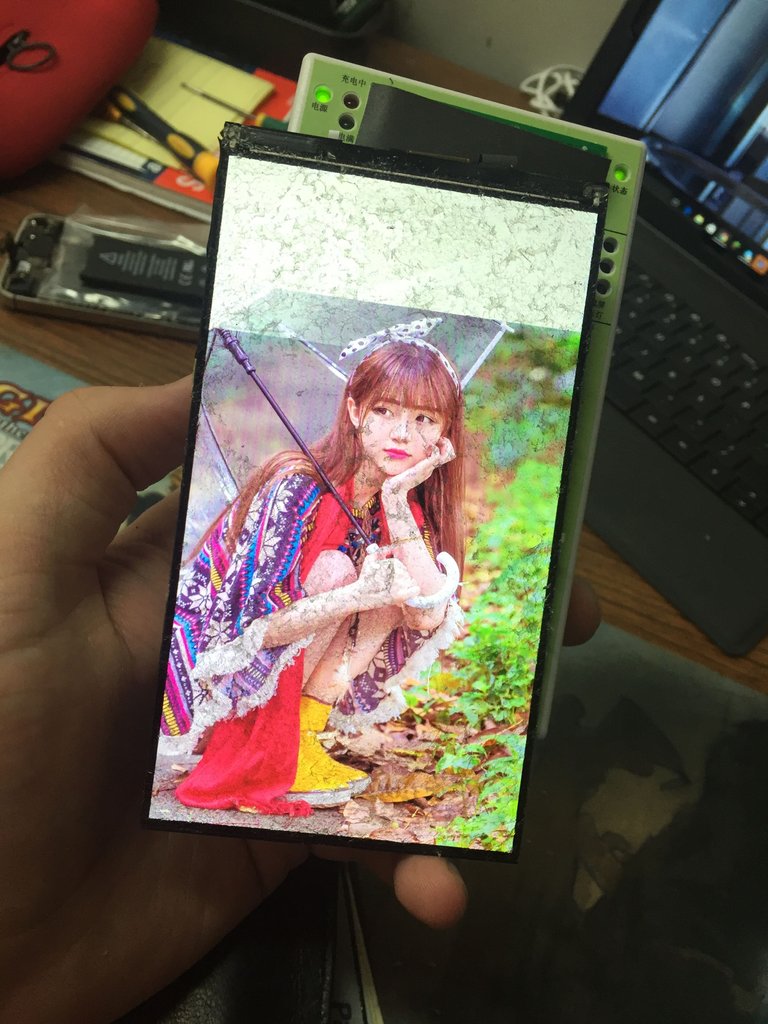

After removing the glass on an iPhone display there is glue left all over the LCD's polarizer layer. It looks like this. (The display is attached to the test box mentioned earlier. If your curious the girl pictured is a picture slide that the chinese programed into the box.)

We then use a machine that heats a razor up to 200 Celsius and cuts through the polarizer / peels it off the display. Below is a iPhone 7 display having the polarizer removed. Very soothing to watch it peel off slowly!

The rest of this process is done in a dust free enviroment we built in our lab. We use machines called Stay Clean Hoods that keep the work environment 99% clean by constantly filtering the air through hepa filters.

Here is where we roll a new polarizer on the display. We use a machine called a Polarizer laminator. This machine also uses a vacuum pump to hold the polarizer aligned on the top while holding it upside down. This machine is used with molds to make sure we get a quick and aligned roll everytime. Very important to have this machine fine tuned to avoid bubbles when rolling.

Once the polarizer is rolled on the display we use a mold to apply a pre assembled part we order that has new glass, frame, and optically clear adhesive. We put this mold into a glass laminator as seen below.

Out of this laminator, the display is then ready for QC and a few small parts we apply by hand. Below you will see a finished product ready to ship to our clients!

![310.JPG]

(

Bubble wrapped up ready to ship!

Would love to answer any questions you may have or even take suggestions for future content about the repair industry. We also have a retail cell phone repair location connected to our small warehouse.

Hope this was as cool of an insight as I'm thinking it might be to someone who doesn't see this every day If your interested in checking us out you can find more content at:

www.glassonlyrepair.com

www.facebook.com/glassonlyrepair

www.instagram.com/glassonlyrepair

Keep on Steeming

Kevin out.

really great post on how you repair some of the newer smartphones, except I'm embarrassed for all the times my amateur piker self has tried taking this on all by myself! lol

Nothing embarrassing about that at all! I have another post coming out about our right to repair next. In the USA our right to repair is under attack by companies like John Deer and Apple. I love everyone who has the heart to take apart their own phone and try to repair it! I appreciate your kind words.

look forward to reading it, and yeah, one more reason more people than ever are fed up with Apple, along with their upcoming screen-attached "irreplaceable Touch ID sensor".

Link: Apple's secret iPhone calibration machine and its Touch ID sensor will allow it to monopolize the repair industry.

Yes this sensor is a pain in our ass! I will have to do some writeups about that as well. Its nice to see that this news is hitting more people then just businesses in the industry. It is important we fight back against this type of monopolization!

Very cool post. Upvoted & resteemed.

Thank you so much for your kind words and share. I really want to share this type of behind the scenes info with more people!

Thanks for the cool pics of the process of replacing the glass at the refurbishment facility where you work.

No thank you for enjoying them!

Hey that's really cool, you got some great tools to do it with.

Nice post

Thank you so much for the comment. I look forward to bringing more insight to our right to repair. Here in the USA we are fighting for the rights to repair our own devices. Pure insanity!

I try to invest in a good case or a tempered glass. Nothing worst than having a broken screen, I've never had one, but I've had customers who've had that problem.

I agree a quality case and a tempered glass are a great way to prevent damage. Especially with the cost of repair nowadays being in the $100-$200 range due to cost of parts!

Great insight into how phone screens get fixed! Thanks.

Hey thank you for the kind words!

You're welcome. 👌

Hey bro i really need to use your service for my Huawei Mate 7 mobile. I have been to several shops and they told me the same story to replace full assembly.

Yes Mate 7 Is a very common repair to be done with full assembly. Where are you located? I am tied in with many repair stores and can get you setup.

Actually i am located in Pakistan. I can send the mobile to you . What will be the cost for glass replacement?

For the mate 7 we would recommend a full assembly. The demand on the glass is low and replacement is equally close in price. I can check with my vendors in china and let you know just in case we can score a deal.

Sure please let me know

I totally enjoy knowing how things are done! Your gifs are better than nothing, but they move so fast! Any chance you can upload actual videos to YouTube and then use the Share code to post here for future articles? Thanks for your consideration.

Absolutely great idea, Let me compile the process into a video and Ill post that as well! Thanks for the feedback!

Yay!!! Looking forward to your videos! THANKS!

This is sick as Hell. Upvoted.

Thanks a ton!

Great post. i am always looking for replacement LCD for my customers phones.

will be in touch :-)