Construct the board by joining 8 alternating colered boards. They should be slightly off square so they can be plained down to square.

Sand the glue off, and plain your plank down to the same thickness as the width of one of the sticks 8 sticks in your plank. This completes the board stock.

Cross cut lengths of at least a half inch thickness from the board stock.

Join 8 of these lengths cut from the boardstock with the endgrain up. Plain off the glue and sand the sides. This completes the board.

Create a frame at least 2 inches tall to fit around the board. Measure the inside diameter 4 sides to fit so each miter is on the corner of your board.

Rip a groove for the drawer that is on the inside of the frame at least a quarter inch up from the bottom of the side.

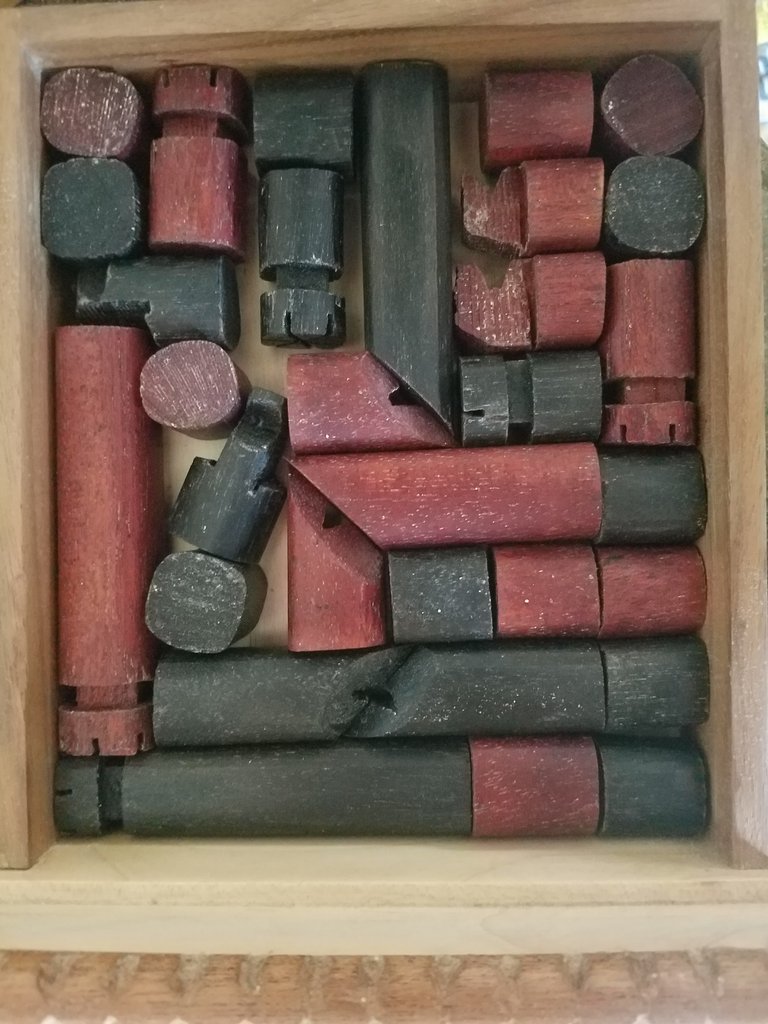

Join 3 sides of the frame around the board, make a drawer to fit the groove, add a handle and make the pieces. To make the pieces I made a dowel and cut it various ways on a band saw. Be careful if you choose to make them this way.

Finish and play.

Issues and problems

I had to cut one sides bishops to be able to fit the pieces in the drawer.

My cat stole a piece and hid it somewhere.

My Cats would bring me gifts, like dead mice they caught outside and brought into the House. With Fish the reverse would happen, lol. A set like this could double as a decorative piece, and you could go crazy with the finish to create whatever look you wanted.

Haha Im sure your cat loved that!

Thanks for the comment, i might get creative woth the finish when i have some time.

Im going to make another one of these soon, I will make it turn out better.

Well there is no right or wrong. You can spend weeks on achieving a finish worthy of a Ferrari, but for something potentially rattling around in a box during transport an oil finish or something more rustic would be more practical and have a character all it's own. As a boat builder there was always the discussion on how much time to spend on paint; the first docking mishap will alter the look of your boat for you, like it or not.

Aha very true a good finish is easy to match and layer for repairs especially for boats. If i paint this set with oil it will last a long time, maybe in a lake even. Sweet job by the way, Ive always dreamed of building a wood boat, bending beams etc, im guessing it means alot of welding ,bolt grinding, and fiberglass fumes with modern commercial vessels, have you ever worked on a wood boat?

Yes. I have built a few wooden boats ranging from 14 to 70 Feet. I never bothered with clinker planking but used strip building, plywood, tortured plywood, and carvel planking once. For modern Hull shapes, strip building in a half mold is probably the most efficient way to get any shape you want without wasting time and energy on steam bending. I've used strip building for hulls ranging from a Canoe to a 32 ft Ian Farrier Trimaran.

You can read about us here