Check out this stuff I've been working on lately.

This is what this table started off as. 1000 bucks worth of walnut. Minus the metal base I suppose, we had someone else do that.

The whole thing had to be shipped in two parts, with both the top and the base being almost too heavy to hold. maybe between 250 - 300 lbs each.

Banannas, I still have bruises on my arms and legs from leveraging them.

This is what I do for my day job.

I dropped out of highschool at 16, and took a woodworking class at a local community college in Oakland CA.

Since then, I've been working in different cabinet shops around the country. Its been about 12 years of cabinetry at this point, and varying in quality from very high end exotic wood custom cabinets in small shops, to cheap plastic laminate cabinets in large industrial shops.

BUT, I googled furniture makers in Detroit, found my favorite one, and knocked on his door with my resume in hand, and I was working the following week. It's nice to be able to take pride in the work you do for a living. I've always been a DIY dude, and I've always felt a very strong sense of pride and fulfillment from making things with my hands. I will sometimes show my girlfriend things I've made 7 or 8 times and ask her to tell me how impressed she is every time.

NOW ITS YOUR TURN!

EXCLAIM YOUR WONDERMENT!

Here's a fleet of stools we just finished up.

Heres some of the process:

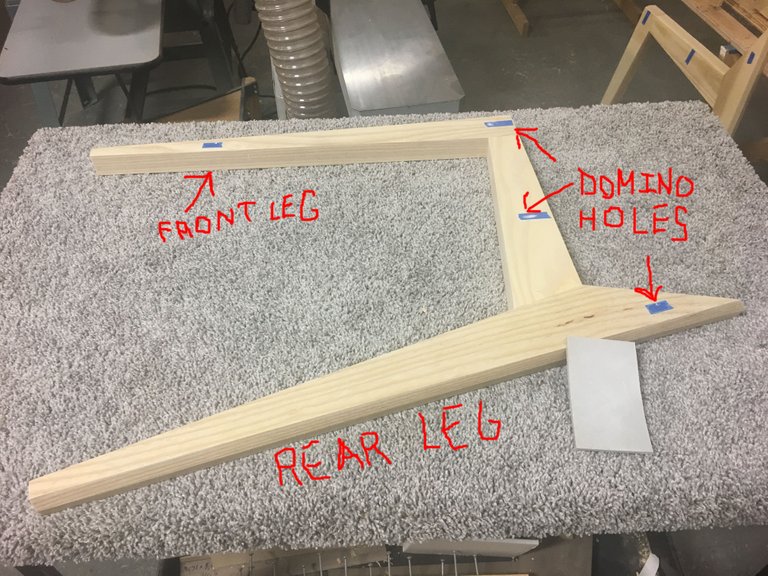

The tape is to cover the domino holes so when we spray finish, it doesn't get in the hole, which could mess up the glue. Dominoes are like dowels, but wide, super easy to use and strong ass hell; but you can only really use them if you have a fancy Festool domino machine. Festool makes very high end (see: overpriced) woodworking machinery and caters mostly to small shops and hobbiests. I've never really seen a well used Festool machine in a larger shop. I'm still unsure about how I feel about that, I consider durability and cost when judging tool quality.

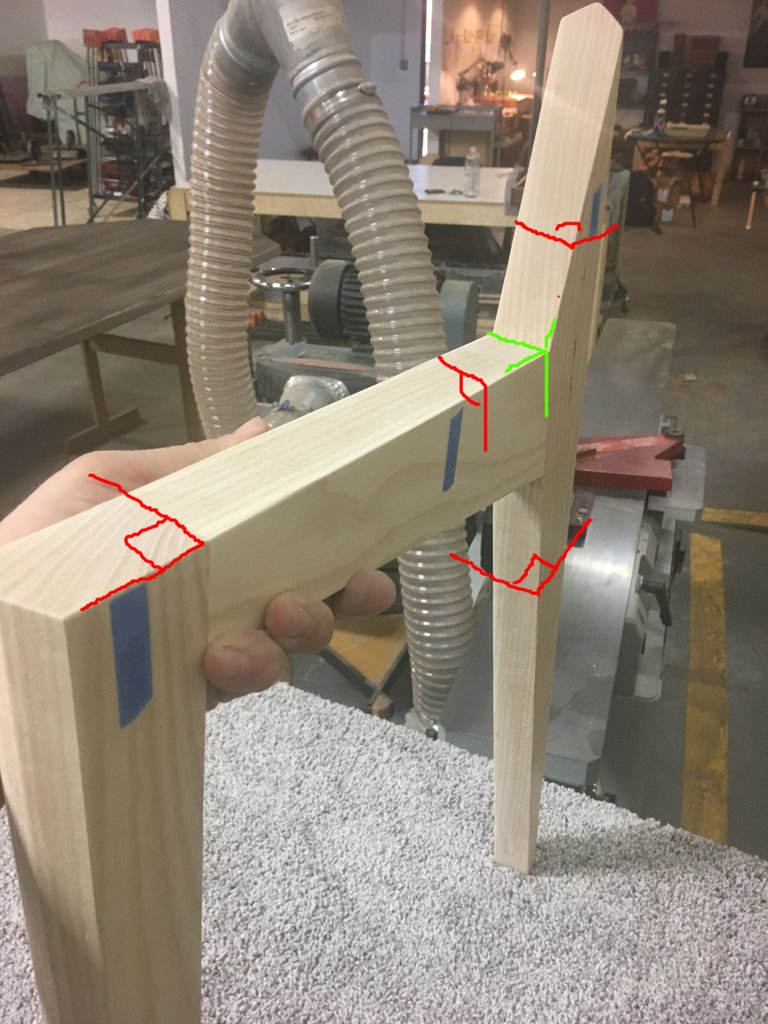

I attempted to highlight the weird angles in this photo. The tapered part of the rear leg had to be cut at a different angle so it would line up and look good with the front leg and stretcher.

I don't know if its easy to see from the photo, but this was fun/frustrating.

Everything drying on our little spraying racks after being finished. We sand to 220 or 360 grit, spray, than sand again with 360 to 400 grit, then spray again. The higher the number, the smoother the sandpaper.

The glue up: We used epoxy because it had a longer working time. Sometimes wood glue only takes 6 minutes before you cant really hammer on it or put pressure on it anymore.

here it is all glued up and some drawing on it to show that theres different angles in funny spots.

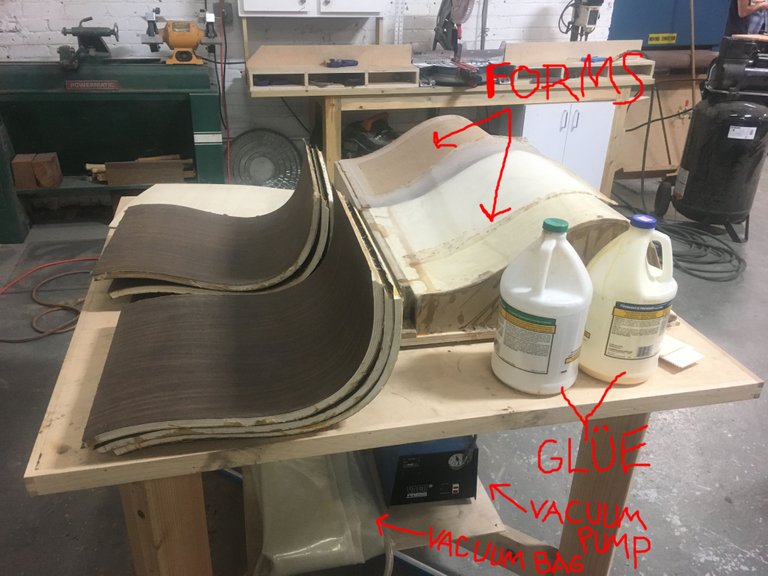

Heres you can see the forms used to make the seat pan. We cut up this fancy "bendy ply" into rectangles, and slathered each one in glue, and put it over that form, and put that in this thing called a vacuum bag, which is like a big industrial sized vacuum sealer some people use for their food. it sucks the wood to the form super tight and holds it for a while.

Then we cut them with a bandsaw, shaped them, sanded them, finished them, attached them, and we made this cool box thats pretty heavy duty, and has a platform, so when the recipient gets their stool, they cut along the bottom and lift the top off the platform.

We took a few photos before we sent them:

Below is another thing I made...... Its a bench... They were featured in a catalog, and people can order them, so now I gotta make more very soon, so I will have tons of good process pictures of these.

I hope I never have to go back to a big factory setting again, its alright money, but its too many hours, and there's very little pride, and they listen to the same stupid radio stations day in and out with the same 100 songs over and over and over.

The Dj is all like: "Journey, every hour, on the hour. Only on GloboCorp Radio, your source for up to 100 of the most commonly agreed upon inoffensive songs."

Also, there is always this inescapable feeling of being taken advantage of. Everywhere I go, there's always this underlying sensation of being stepped upon.

Unless its a smaller shop with more interesting detailed work. Working is often much easier on the soul in those places.

Anyway, tell me what you think.

Really cool work! I've made a few things as my personal little "woodwork" projects. But nothing this complicated.

Thanks! I appreciate it.

I like to believe anyone is capable of creating anything. I'm sure that if you felt like it and had the time, you could whip out anything you wanted to.

Real nice work!

Beautiful man, really nice work! I like doing some small projects with wine barrels, and have already learned a lot from your post!

Congratulations @slimysammy! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!