A. Wastewater Treatment With Rotating Biological

Contactor (RBC) Process

Rotative biological contactor abbreviated as RBC is one of the wastewater treatment technologies that contain high biological organic pollutants with attached culture system. The working principle of wastewater treatment with RBC ie waste water containing organic pollutants is contacted with a layer of micro-organisms (microbial film) attached to the surface of the media inside a reactor.

The media in which biological films are attached are discs of light polymer or plastic materials and are arranged from a row on a shaft to form a module or package, subsequently the module is rotated slowly in a partially immersed state into the flowing waste water continuously into the reactor.

In this way the micro-organisms of miaslanya bacteria, algae, protozoa, fungi, and others grow attached to the surface of the rotating media form a layer consisting of micro-organisms called biofilm (biological layer). Micro-organisms will decompose or retrieve existing organic compounds in water and take water-soluble oxygen or from air for their metabolic processes, thereby reducing the content of organic compounds in wastewater.

When the biofilm attached to the thin disk medium is immersed in the waste water, the micro-organism absorbs the organic compounds present in the waste water flowing on the surface of the biofilm, and when the biofilm is above water, the micro-organism absorbs oxygen from air or oxygen dissolved in water to decompose organic compounds. The resulting decomposition of these organic compounds is used by micro-organisms for the process of proliferation or metabolism.

The resulting compound of metabolism of the micro-organism will be released from the biofilm and carried away by the water or gas stream will be dispersed into the air through the cavities present on the medium, whereas for the suspended solid (SS) will be retained on the surface of the biological layer (biofilm ) and will decompose into a water-soluble form.

The growth of micro-organisms or biofilms is getting thicker, until finally because of the gravity will partially peel off the medium and carried out the flow of water out. Furthermore, the micro-organisms on the surface of the medium will grow again with the equilibrium until there is equilibrium according to the content of organic compounds present in the waste water. In simple terms the process of decomposition of organic compounds by micro-organisms in RBC can be described as in Figure III.3.

The advantages of the RBC system are simple operation and construction processes, relatively smaller energy requirements, do not require large amounts of air, muds are relatively small compared to active sludge processes, and relatively no froths. While the shortcomings of the RBC system that is sensitive to temperature.

Figure III.3: Mechanism of the process of decomposition of organic compounds by micro-organisms in RBC

Figure III.3: Mechanism of the process of decomposition of organic compounds by micro-organisms in RBC

B.Processing

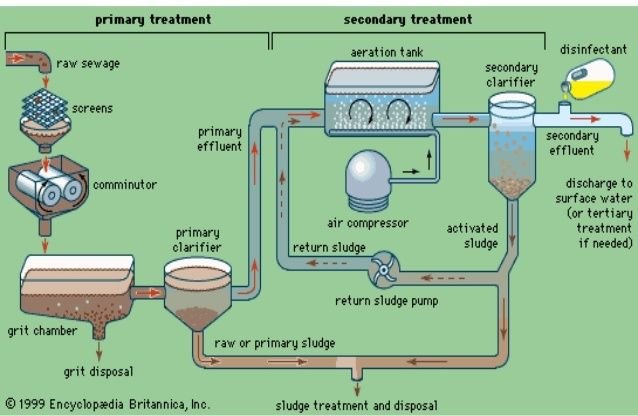

* Generally, the process of wastewater treatment with RBC system consists of sand separator, basin basin, flow control basin, rotary biological reactor (RBC), final settling tub, chlorination tub, and mud treatment unit. Diagram of wastewater treatment process with RBC system is as in figure III.4.

Figure III.4: Wastewater treatment process diagram with RBC system.

1.Sand Separator

* Wastewater is flowed quietly into the sand separator, so that dirt in the form of sand or rough sludge can be deposited. While floating waste such as garbage, plastic, garbage and other fabrics stuck on the sarangan (screen) mounted on the inlet of the sand separator pool.

2.Initial Settlement Tub

* From the sand separator / sandbag, the waste water is flowed to the original basin. In this initial settling basin the mud or suspended solids are largely settled. The residence time in the initial sediment bath is 2 - 4 hours, and the settling sludge is collected and pumped into a mud settling basin.

3.Flow Control Tub

* If the discharge of the waste water exceeds the planning capacity, the excess waste water discharge is flowed to the flow control basin for temporary storage. At the time of the flow down / small flow, the wastewater in the control tub is pumped into the initial settling tub together with the new waste water in accordance with the desired discharge.

4.Contactor (reactor) Biological Play

* In the tub of this contactor, the media is a thin disk of polymer or plastic material in bulk, attached or assembled on a shaft, rotated slowly in a partially immersed state into the waste water. The stay time in the container tub is approximately 2.5 hours. In such conditions, micro-organisms will grow on the surface of the rotating medium, forming a biological film (film). Biological films consist of various types / spicies of micro-organisms such as bacteria, protozoa, fungi, and others. Micro-organisms that grow on the surface of this medium will describe the organic organisms that exist in the waste water. The biological lapsian is getting thicker and thicker because its gravity will peel away and the mud will be carried out. Furthermore, biological laisons will grow and expand again on the surface of the media by itself.

5.End Settlement Tub

* The waste water coming out from the tub of the contactor (reactor) is then flowed to the final settling basin, with a settling time of about 3 hours. Compared with the active sludge process, the sludge derived from the RBC is easier to settle, since the size is larger and heavier. The overflow water from the relative's final settling tub is clear, then flowed to the chlorination tub. As for the sludge that settles in the bottom of the tub at the pump to the sludge filler tub together with the sludge from the initial settling basin.

6.Chlorination Tub

* Processed water or runoff water from the final sedimentary tub still contains coli bacteria, pathogenic bacteria, or viruses that are potentially infected to the surrounding community. To overcome this, the wastewater coming out of the final settling tub is flown to the chlorination tub to kill the pathogenic micro-organisms present in the water. In chlorinated water, wastewater is spiked with chlorine compound with a certain dose and contact time so that all micro-organisms of the pathogen can be switched off. Furthermore from the chlorination water of waste water may be discharged to water bodies.

7.Mud Solid Tub

* Mud derived from the initial settling basin and the final settling basin are collected in a slurry container bath. In the tub the mud is stirred slowly then concentrated in a manner of about 25 hours so that the mud settles, then the supernatant water at the top is flowed to the initial sedimentary bath, while the concentrated sludge is pumped into the mud dryer or accommodated in the tub alone and periodically sent to mud processing centers elsewhere.

C. RBC Advantages and Weaknesses

Some advantages of wastewater treatment process with RBC system include:

- Easy operation and maintenance.

- For small capacity / packet, compared with active sludge process lower energy consumption.

- Can be installed several stages (multi-stage), so resistant to fluctuations in the load processing.

- Nitrifying reactions are easier to occur, resulting in greater ammonium removal efficiency.

- No bulking or foam occurs (foam) as in the active sludge process.

While some weaknesses of wastewater treatment process with RBC system such as:

- Controlling the number of micro-organisms is difficult.

- Sensitive to temperature changes.

Sometimes the BOD concentration of processed water is still high. - Can cause hair worm growth, as well as occasionally arise a less unpleasant Odor.